PCBN (Polycrystalline Cubic Boron Nitride) cutting tools are among the most advanced and durable tools available for machining hard and wear-resistant materials. They are widely used in industries where precision, heat resistance, and high-performance cutting are required. Below are some key application areas where PCBN cutting tools excel.

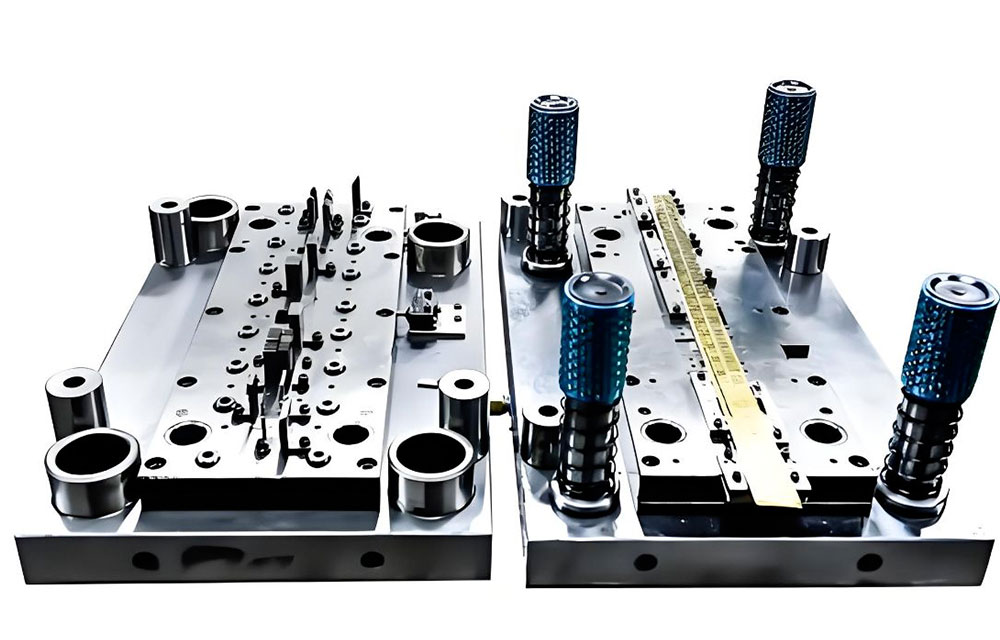

Machining of Hardened Steels

One of the most prominent applications of a PCBN cutting tool is in the machining of hardened steels. Due to their exceptional hardness and wear resistance, PCBN tools can easily handle materials that are difficult to machine using traditional carbide tools. This makes them ideal for manufacturing automotive components, aerospace parts, and cutting tools that require high hardness and precision.

PCBN cutting tools are capable of maintaining sharp edges even under high cutting speeds, significantly improving the quality and efficiency of machining hardened steel.

Precision Machining of Cast Iron

PCBN cutting tools are particularly well-suited for machining cast iron, including gray cast iron, ductile iron, and high-chromium cast iron. Cast iron, with its abrasive nature, rapidly wears out conventional cutting tools, but PCBN tools stand up to the abrasive forces and provide a longer tool life.

The high thermal stability and wear resistance of PCBN make it the go-to solution for the precision machining of cast iron components such as engine blocks, transmission housings, and industrial machinery.

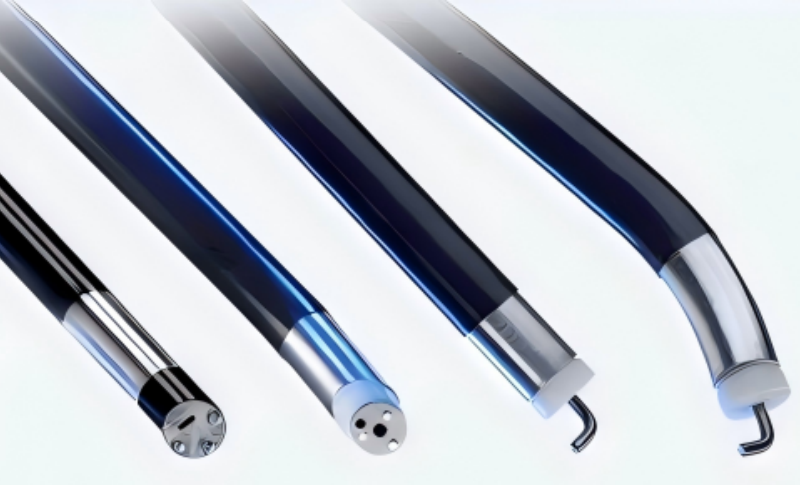

High-Temperature Alloy Machining

PCBN cutting tools are invaluable for machining high-temperature alloys, including superalloys and nickel-based alloys. These materials are commonly used in the aerospace and energy sectors due to their excellent high-temperature strength and resistance to oxidation.

PCBN tools are capable of machining these challenging materials while maintaining their integrity, providing superior surface finishes, and minimizing tool wear. This makes them essential for manufacturing critical components like turbine blades, aerospace engine parts, and heat-resistant fasteners.

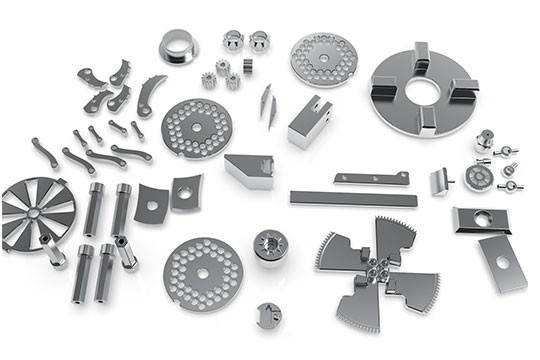

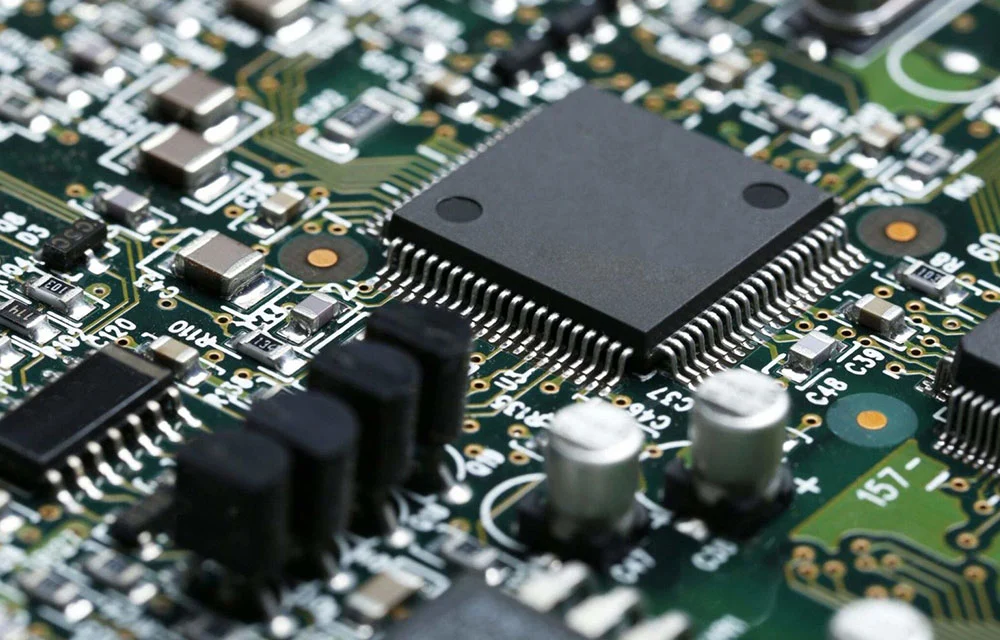

Non-Ferrous Metal Machining

Although PCBN tools are predominantly used for ferrous materials, they also excel in the machining of non-ferrous metals such as copper, aluminum, and titanium. In applications where high precision and excellent surface finish are required, a PCBN cutting tool provides unmatched performance.

For industries such as medical device manufacturing, electronics, and automotive, PCBN tools are used to machine components such as heat exchangers, valve seats, and electrical connectors, ensuring durability and dimensional accuracy.

| Application Area | Benefits of PCBN Cutting Tool |

|---|---|

| Hardened Steels | Superior hardness and wear resistance, improved tool life |

| Cast Iron | Excellent wear resistance against abrasive materials |

| High-Temperature Alloys | High thermal stability, precise cutting in extreme conditions |

| Non-Ferrous Metals | Excellent surface finish and precision cutting |

PCBN cutting tools from JoyJet offer exceptional performance across a wide range of industries. Their ability to withstand extreme temperatures, cutting speeds, and abrasive materials makes them the ideal solution for manufacturers needing precision, durability, and efficiency. Whether machining hardened steels, cast iron, high-temperature alloys, or non-ferrous metals, PCBN cutting tools are critical for meeting the demands of modern manufacturing. JoyJet ensures that each PCBN cutting tool delivers superior reliability and performance in the most demanding applications.