In line with our commitment to green manufacturing and environmental sustainability, Joyjet offers professional regrinding services for insert tools. Whether it's a standard insert or a specialized MCD tool, our services support multiple regrinding cycles and coating restoration to significantly extend tool life and maximize utilization. Contact us today for a free first-time regrinding service. For businesses looking for diamond tools wholesale options, our sharpening services can also complement their inventory management by extending tool life.

Tool Evaluation

Customers send worn tools → Joyjet inspects the wear level (such as edge chipping, coating peeling, etc.) and provides a quote.

Customization Plan

Select the sharpening process based on the tool type (e.g., ball nose end mills, step drills, or even a delicate PCD micro drill) for procedures such as edge sharpening or coating re-coating.

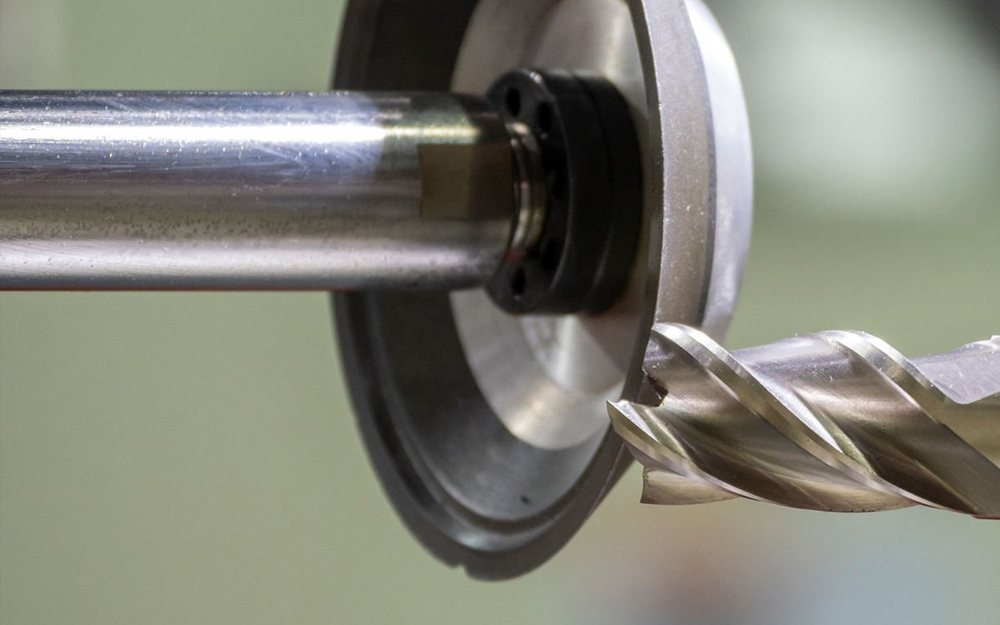

Precision Sharpening

CNC grinding + manual quality inspection (microscope inspection of edge integrity).

Delivery & After-Sales

A sharpening report is provided (e.g., dimensional comparison chart), and some services may include a performance warranty period.

Q: What is the lifespan of sharpened tools?

A: Typically 70%–90% of the new tool's lifespan, depending on the tool material and initial wear condition.

Q: Do you support non-standard tools?

A: Non-standard tool measurement and custom sharpening services are available (original manufacturer parameters or samples are required), covering everything from a simple drill to a complex mcd end mill.