Maximize machining efficiency with JoyJet PCD Inserts. Engineered for superior wear resistance and extended tool life, our inserts deliver precision cutting in non-ferrous metals and composites. Ideal for automotive, aerospace, and electronics industries, cutting tool inserts from JoyJet's PCD Insert factory ensures flawless finishes and reduced downtime. Trust the leader in high-performance diamond tools wholesale services.

Extremely High Hardness (≈8000 HV)

Excellent Wear Resistance, ideal for high-abrasion materials.

Aluminum Alloy Machining: Engine blocks, wheel hubs, transmission housings, etc.

Composites: Carbon fiber reinforced plastic (CFRP), fiberglass, etc.

Non-Ferrous Metals: Copper, brass, bronze, etc.

Other Materials: Graphite electrodes, ceramics, rigid plastics, etc.

Material Properties: Select the appropriate grade based on the workpiece material.

Cutting Parameters: Optimize speed, feed rate, and cutting depth to maximize PCD performance.

Insert Geometry: Choose the cutting edge design based on the type of machining (roughing/finishing).

Cooling Method: It is recommended to use cutting fluids or air cooling to improve tool life.

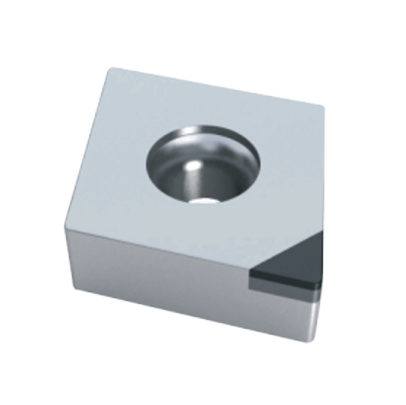

| Insert Shape | Type | γo Rake angle | Φd Inscribedcirdle | S Thickness | Φd1 Inner hole diameter | r Radius |

| CNGA 090302 | / | 9.525 | 3.18 | 3.18 | 0.2 |

| CNGA 090304 | / | 9.525 | 3.18 | 3.18 | 0.4 | |

| CNGA 090306 | / | 9.525 | 3.18 | 3.18 | 0.6 | |

| CNGA 090308 | / | 9.525 | 3.18 | 3.18 | 0.8 | |

| CCGW 060202 | / | 6.35 | 2.38 | 2.8 | 0.2 | |

| CCGW 060204 | / | 6.35 | 2.38 | 2.8 | 0.4 | |

| CCGW 060206 | / | 6.35 | 2.38 | 2.8 | 0.6 | |

| CCGW 060208 | / | 6.35 | 2.38 | 2.8 | 0.8 | |

| CCGW 09T308 | / | 9.525 | 3.97 | 4.4 | 0.2 | |

| CCGW 09T306 | / | 9.525 | 3.97 | 4.4 | 0.4 | |

| CCGW 09T304 | / | 9.525 | 3.97 | 4.4 | 0.6 | |

| CCGW 09T308 | / | 9.525 | 3.97 | 4.4 | 0.8 | |

| CPGT 090302 | 5°-10° | 9.525 | 3.18 | 4.4 | 0.2 | |

| CPGT 090304 | 5°-10° | 9.525 | 3.18 | 4.4 | 0.4 | |

| CPGT 090306 | 5°-10° | 9.525 | 3.18 | 4.4 | 0.6 | |

| CPGT 090308 | 5°-10° | 9.525 | 3.18 | 4.4 | 0.8 |

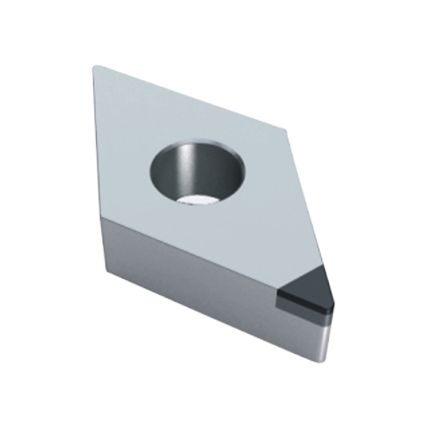

| Insert Shape | Type | Φd Inscribedcirdle | S Thickness | Φd1 Inner hole diameter | r Radius |

| VNMA 160402 | 4.76 | 3.8 | 3.8 | 0.2 |

| VNMA 160404 | 4.76 | 3.8 | 3.8 | 0.4 | |

| VNMA 160408 | 4.76 | 3.8 | 3.8 | 0.8 | |

| VNMA 160410 | 4.76 | 3.8 | 3.8 | 1 | |

| VNMA 160412 | 4.76 | 3.8 | 38 | 12 | |

| VBMW 160404 | 4.76 | 4.4 | 44 | 0.4 | |

| VBMW 160406 | 4.76 | 44 | 44 | 0.6 | |

| VBMW 160408 | 4.76 | 44 | 44 | 0.8 | |

| VBNW 160410 | 4.76 | 44 | 44 | 1 | |

| VBNW 160412 | 4.76 | 44 | 44 | 1.2 | |

| VCGW 160404 | 4.76 | 4.4 | 4.4 | 0.4 | |

| VCGW 160408 | 4.76 | 44 | 4.4 | 0.8 | |

| VCGW 160410 | 4.76 | 44 | 4.4 | 1 | |

| VCGW 160412 | 4.76 | 44 | 4.4 | 12 | |

| VPGW 080202 | 2.38 | 23 | 2.3 | 0.2 | |

| VPGW 080204 | 2.38 | 2.3 | 2.3 | 0.4 | |

| VPGW 080208 | 2.38 | 2.3 | 2.3 | 0.8 |

| Insert Shape | Type | Φd Inscribedcirdle | S Thickness | Φd1 Inner hole diameter | r Radius |

| DNMA 150402 | 12.7 | 4.76 | 5.16 | 0.2 |

| DNMA 150404 | 12.7 | 4.76 | 5.16 | 0.4 | |

| DNMA 150408 | 12.7 | 4.76 | 5.16 | 0.8 | |

| DNMA 150410 | 12.7 | 4.76 | 5.16 | 1 | |

| DNMA 150412 | 12.7 | 4.76 | 5.16 | 12 | |

| DCGW 090202 | 7.94 | 238 | 3.4 | 0.2 | |

| DCGW 090204 | 7.94 | 238 | 3.4 | 0.4 | |

| DCGW 090206 | 7.94 | 2.38 | 3.4 | 0.6 | |

| DCGW 090208 | 7.94 | 2.38 | 3.4 | 0.8 | |

| DPGW 070202 | 6.35 | 2.38 | 2.8 | 0.2 | |

| DPGW 070204 | 6.35 | 2.38 | 2.8 | 0.4 | |

| DPGW 070206 | 6.35 | 2.38 | 2.8 | 0.6 | |

| DPGW 070208 | 6.35 | 2.38 | 2.8 | 0.8 |

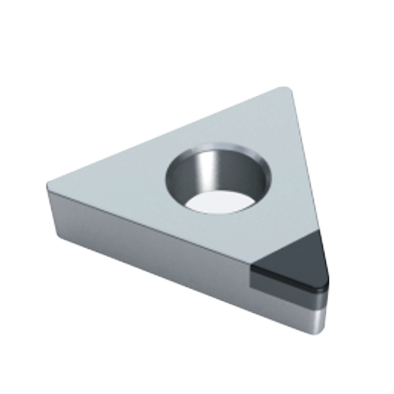

| Insert Shape | Type | Φd Inscribedcirdle | S Thickness | Φd1 Inner hole diameter | r Radius |

| TNGA 160404 | 9.525 | 4.76 | 3.8 | 0.4 |

| TNGA 160408 | 9.525 | 4.76 | 3.8 | 0.8 | |

| TNGA 160412 | 9.525 | 4.76 | 3.8 | 12 | |

| TNGA 160416 | 9.525 | 4.76 | 3.8 | 1.6 | |

| TCGW 060202 | 3.97 | 2.38 | 2.2 | 0.2 | |

| TCGW 060204 | 3.97 | 2.38 | 2.2 | 0.4 | |

| TPGW 080202 | 4.76 | 2.38 | 2.4 | 0.2 | |

| TPGW 080204 | 4.76 | 2.38 | 2.4 | 0.4 | |

| TPGW 080206 | 4.76 | 2.38 | 2.4 | 0.6 |