JOYJET's PCD (Polycrystalline Diamond) micro drills are engineered for ultra-precision micro-hole drilling in challenging materials such as high-silicon aluminum alloys, copper alloys, ceramics, and composites. As an experienced diamond tools wholesale supplier, we provide the PCD micro drill series that offers exceptional tool life, extreme accuracy, and reliable process stability for demanding micro-machining applications. Contact us now to inquire about pricing and see how our PCD cutting tools can benefit your business.

Ultra-High Hardness: Diamond hardness up to HV8000–10000

Minimized Built-Up Edge: These diamond micro drills reduce burr formation and prevent wall tearing, extending drill life

High-Rigidity Shank: Our PCD micro drill series is made with ultra-fine grain carbide substrates to reduce the risk of micro drill breakage

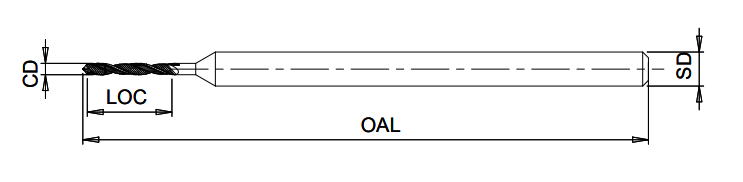

| Image | Order no. | Cutting Diameter (+0.015) | Shank Diameter(h6) | LOC(+0.8) | OAL(+1.5) |

| SJM107 | 0.3 | 3mm or 1/8 | 5.5 | 50 |

| SJM482 | 0.4 | 3mm or 1/8 | 5.5 | 50 | |

| SJM936 | 0.45 | 3mm or 1/8 | 7 | 50 | |

| SJM251 | 0.48 | 3mm or 1/8 | 7 | 50 | |

| SJM804 | 0.5 | 3mm or 1/8 | 7 | 50 | |

| SJM319 | 0.6 | 3mm or 1/8 | 7 | 50 | |

| SJM675 | 0.75 | 3mm or 1/8 | 7 | 50 | |

| SJM042 | 0.8 | 3mm or 1/8 | 7 | 50 | |

| SJM588 | 1 | 3mm or 1/8 | 7 | 50 |

Micro drilling is a precision machining process used to create extremely small and precise holes, typically with diameters ranging from a few micrometers to a few millimeters. This process is essential in various high-tech industries where precision and accuracy are critical. Here are some key aspects of micro drilling:

Applications: Micro drilling is commonly used in the electronics industry for creating holes in printed circuit boards (PCBs), in the medical field for manufacturing medical devices and implants, in the aerospace industry for precision components, and in the automotive industry for fuel injectors and other small parts.

Tools: Micro drilling requires specialized tools, such as micro drills made from materials like tungsten carbide or polycrystalline diamond (PCD). These tools are designed to maintain sharpness and precision even at very small scales. For those interested in acquiring these high-quality instruments, JOYJET caters to diamond tools wholesale demands.

Equipment: High-precision drilling machines, often CNC (Computer Numerical Control) machines, are used for micro drilling. These machines offer the necessary control and stability to achieve the required precision.

Challenges: Micro drilling presents several challenges, including tool wear, heat generation, and maintaining accuracy at such small scales. To mitigate these, a reliable diamond tool sharpening service can significantly extend tool life and maintain precision.

Techniques: Various techniques can be used in micro drilling, including laser drilling, electrical discharge machining (EDM), and mechanical drilling. The choice of technique depends on the material being drilled and the specific requirements of the application.

PCD Micro Drills are optimized for machining hard, brittle, and abrasive non-ferrous materials, including:

Monocrystalline Silicon: Used in semiconductor components like gas distribution plates and wafer carriers.

Quartz/Fused Silica: Common in semiconductor wafer processing for boats, pedestals, and shower plates.

Ceramics: Such as alumina (Al2O3) and silicon carbide (SiC), used in electronics and die/mold industries.

Composites: Including CFRP, GFRP, and carbon-phenolic materials, prevalent in aerospace.

Non-Ferrous Metals: Aluminum, magnesium, copper, and their alloys, often used in automotive and electronics.

Other Materials: Graphite, sapphire, green ceramics, and wear-resistant plastics.

| Feature | PCD Micro Drills | Carbide Drills |

|---|---|---|

| Hardness | 5000–8000 HK (extremely high) | 1800–2400 HK (very high) |

| Wear Resistance | Exceptional for abrasive non-ferrous materials | Good, but wears faster in abrasive materials |

| Tool Life | Up to 50–250x longer in suitable materials | Shorter in abrasive applications |

| Thermal Conductivity | High, reduces overheating | Good, but less effective than PCD |

| Applications | Non-ferrous, composites, ceramics | Steels, cast iron, some non-ferrous metals |

| Cost | Higher initial cost, but lower cost-per-hole | Lower initial cost, higher replacement frequency |

JoyJet, a leader in diamond tool manufacturing, offers:

High-Quality PCD Micro Drills: Designed for precision and durability in demanding applications.

Custom Solutions: Tailored tools for specific materials and machining tasks.

Professional Sharpening Services: Extends tool life and maintains performance.

Technical Expertise: Over a decade of experience in precision machining and tool production.

Timely Delivery: Efficient production and logistics to meet project deadlines.

For more information or to request a quote, contact JoyJet today.