The manufacturing of optical components demands exceptional precision, surface quality, and tool stability. Diamond tools wholesale often include MCD inserts, which are widely recognized in this field for their ability to maintain sharp cutting edges while machining hard and brittle materials, such as glass, sapphire, and optical crystals. Designed for ultra-precision applications, these inserts excel in delivering smooth finishes, maintaining dimensional accuracy, and reducing surface defects.

The exceptional material properties of MCD inserts make them particularly suited for optical component machining. These inserts are made from monocrystalline diamond, which offers unmatched hardness and thermal conductivity. This combination allows the cutting edge to remain extremely sharp, even under high-speed machining conditions, and provides excellent resistance to wear. The hardness of MCD inserts ensures that delicate optical materials can be cut without causing micro-cracks or surface chipping, while their thermal conductivity effectively dissipates heat generated during cutting. As a result, MCD inserts maintain both the dimensional accuracy and surface integrity required in the production of lenses, prisms, and other optical elements.

MCD inserts are widely applied in the precision machining of lenses, prisms, optical mirrors, and other components where surface finish and tight tolerances are critical. When working with hard crystalline materials, conventional tools often struggle to maintain surface quality, leading to scratches or uneven textures. The fine cutting ability of MCD inserts minimizes such defects, enabling consistent and smooth optical surfaces. Additionally, their stability allows them to perform under continuous operation without losing cutting edge sharpness. For high-precision applications, such as infrared optics or medical imaging lenses, MCD inserts ensure that the final component meets exacting specifications while reducing the need for post-processing polishing.

The use of MCD inserts directly impacts the quality and efficiency of optical component production. By maintaining a sharp edge over prolonged machining cycles, these inserts reduce tool-induced surface irregularities and maintain geometric accuracy in the finished component. Their excellent wear resistance ensures that high-volume production can be carried out without frequent tool changes, while their thermal management properties prevent localized overheating, which could otherwise lead to dimensional deviations or micro-fractures in the optical material. The combination of sharpness, wear resistance, and heat dissipation makes MCD inserts an indispensable tool for ultra-precision cutting tasks in optical manufacturing. For harder materials, some manufacturers also integrate tools from CBN inserts factory to optimize finishing processes.

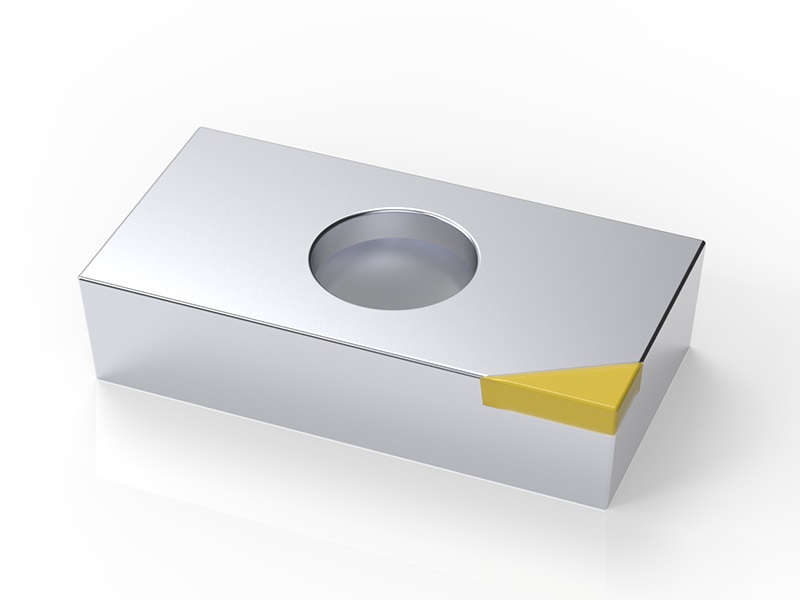

Choosing the appropriate MCD inserts depends on both the material of the optical component and the desired surface finish. For softer optical materials, a finer MCD grain size may be preferred to achieve ultra-smooth surfaces, while harder crystalline materials require inserts with higher fracture toughness to avoid chipping. The geometry of the insert also plays a critical role in controlling cutting forces and chip removal during machining. Proper selection ensures that the insert maintains edge integrity, delivers consistent surface quality, and optimizes machining efficiency. JoyJet's range of MCD and CVD inserts provides options tailored for these varying applications, supporting precise, stable, and reliable cutting performance.

In high-precision optical manufacturing, MCD inserts provide advantages that are difficult to achieve with conventional tools. Their ability to machine hard, brittle, or heat-sensitive materials while maintaining surface integrity is unmatched. The combination of sharpness, durability, and thermal stability ensures consistent quality across multiple components and minimizes the risk of tool-induced defects. For industries producing lenses, mirrors, and complex optical elements, MCD inserts enable faster production cycles, improved surface finishes, and higher reliability. With their specialized design and material characteristics, these inserts are essential for achieving the precision required in advanced optical applications.

By understanding the capabilities of MCD inserts and their specific application in optical component machining, manufacturers can enhance surface quality, maintain dimensional accuracy, and achieve reliable, high-precision results. JoyJet's MCD and CVD inserts provide a dependable solution for ultra-fine machining tasks, ensuring optimal performance in the production of lenses, prisms, mirrors, and other precision optical components.