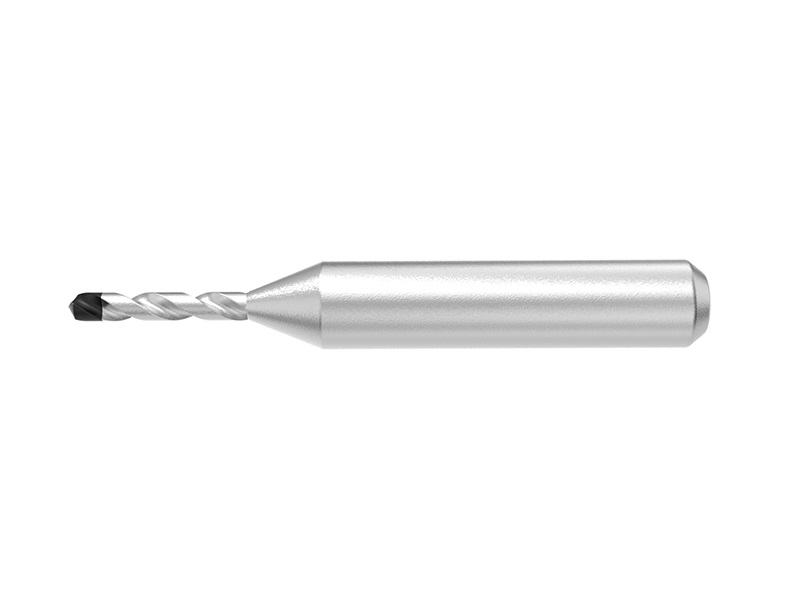

In the field of precision manufacturing, the demand for tools capable of achieving micron-level accuracy has been growing rapidly. The pcd micro drill stands out as an indispensable solution for machining delicate and demanding materials such as non-ferrous metals, composites, and hard ceramics. Its polycrystalline diamond cutting edge offers extreme hardness and wear resistance, making it possible to achieve clean, burr-free holes with exceptional dimensional accuracy. For industries like electronics and aerospace, where even the smallest imperfections can lead to performance issues, PCD micro drills provide consistent reliability. JoyJet, with over a decade of technical expertise, integrates advanced production methods to ensure these drills maintain both stability and longevity during the most challenging operations.

The unique structure of a PCD cutting edge gives the pcd micro drill several advantages over traditional carbide drills. The ultra-sharp geometry reduces cutting forces, allowing smoother drilling at high speeds while minimizing the risk of tool breakage. Additionally, its resistance to wear enables significantly longer tool life, reducing the need for frequent replacements. For micro-scale drilling operations—such as circuit boards, precision molds, or medical components—this extended tool life translates into better productivity and cost efficiency. JoyJet, as both a tool user and a manufacturer, has refined its PCD micro drills through real-world testing, ensuring they consistently meet the extreme demands of fine-detail machining.

The superiority of PCD micro drills becomes clear when compared with conventional carbide or high-speed steel micro drills:

Feature | PCD Micro Drill | Conventional Micro Drill |

Tool Life | Very long, up to 10–20 times longer | Short, requires frequent replacement |

Precision in Small Diameters | Extremely high, consistent micron-level holes | Moderate, prone to deviation |

Resistance to Wear | Excellent, suitable for abrasive materials | Limited, rapid wear in hard materials |

Surface Finish Quality | Near mirror-like finishes with no burrs | Rougher edges, often require polishing |

Cost Efficiency Over Time | High initial investment, low lifecycle cost | Low initial cost, high replacement cost |

This comparison highlights how PCD micro drills, while initially more costly, deliver superior long-term efficiency and machining results that conventional tools cannot achieve, especially in fine-detail applications.

The pcd micro drill plays a critical role in several industries where precision is non-negotiable. In electronics, these drills are essential for creating micro-holes in circuit boards and semiconductor components. In mold making, they enable the accurate production of fine features that define the quality of molded parts. Aerospace manufacturers rely on PCD drills to machine lightweight alloys and composite materials with extreme precision, while the medical sector depends on them for the fabrication of surgical tools and implants. JoyJet combines deep application experience with advanced inspection systems to ensure every drill delivers consistent performance in such critical environments.

Beyond accuracy, the long-term reliability of pcd micro drills is one of their most significant benefits. Their ability to maintain sharpness and stability under high-speed operations reduces downtime associated with tool changes, leading to smoother workflows and improved overall efficiency. This stability ensures that manufacturers can meet high-volume demands without compromising product quality. By emphasizing innovation, customization, and strict quality control, JoyJet ensures that its PCD micro drills provide the durability, performance, and consistency required for modern high-precision industries.