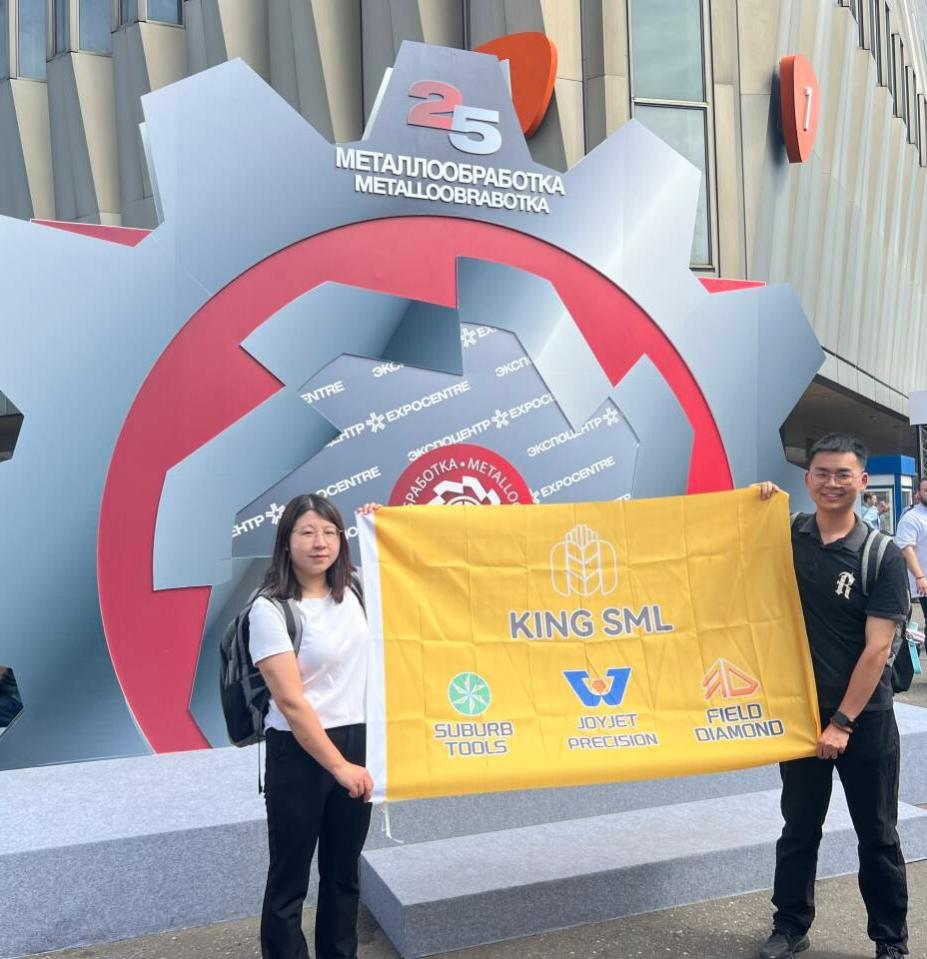

Metalloobrabotka 2025 in Moscow provided a comprehensive view of the cutting tools industry's ongoing transformation. Across five specialized halls at the Expocentre, advanced machining centers, automation systems, and materials processing technologies reflected the region’s growing focus on intelligent, high-efficiency manufacturing.

Metalloobrabotka is one of Russia’s largest industrial exhibitions. While its foundation lies in machine tool technology, the show encompasses the full spectrum of metal processing—from material preparation to precision tooling—highlighting the growing interdependence between machining systems and advanced cutting solutions.

During the show, JoyJet closely followed developments in high-performance cutting tools applications. Conversations with local manufacturers and system integrators revealed increasing demand for PCD insert solutions that combine durability, precision, and compatibility with automated production lines.

JoyJet’s technical team focused on key application areas where material-specific insert performance is critical. JoyJet’s PCD and CBN inserts, along with our CVD, carbide, and ceramic inserts, are engineered to meet these challenges—delivering extended tool life and consistent performance in demanding materials like hardened steel, cast iron, aluminum alloys, and composites.

This year’s exhibition also emphasized the importance of cutting tool adaptability in response to shifting production needs. From batch machining to high-volume precision runs, customers are looking for cutting tool technologies that can reduce downtime and maintain surface integrity under complex conditions.

JoyJet continues to invest in R&D and product engineering to meet these evolving expectations. Whether for turning, milling, or fine finishing, our full line of superhard and PCD tools is built to support manufacturers in pushing productivity and precision forward.

Ready to enhance your machining performance with trusted insert technologies? Contact us for tailored solutions in PCD, CBN, CVD, carbide, and ceramic inserts.