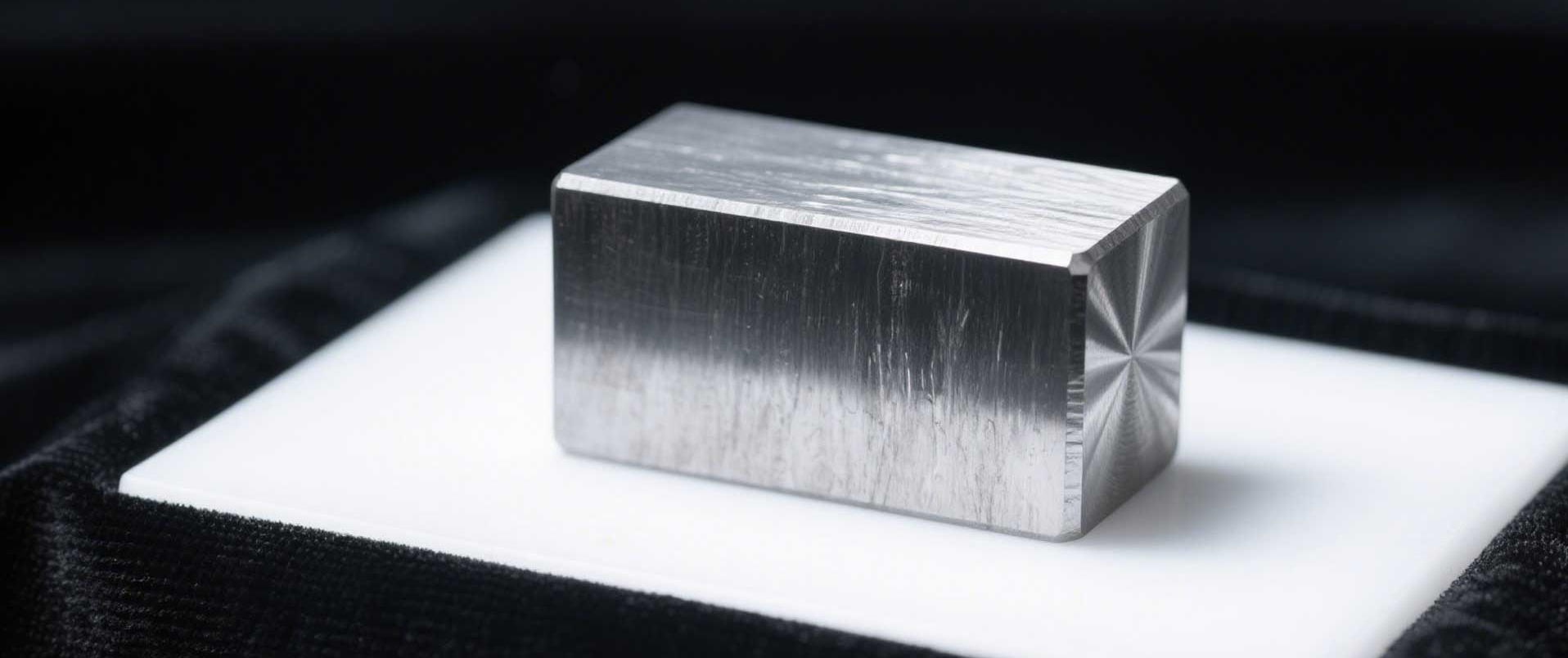

In today's manufacturing industry, Tungsten Carbide (WC) has become an indispensable material for cutting tools, molds, and wear-resistant parts due to its outstanding combination of properties. This composite material, composed of tungsten carbide and cobalt binder, perfectly balances three key indicators: hardness, toughness, and heat resistance.

The core advantages of Tungsten Carbide are:

Ultra-high hardness: HRA90-93, 2-3 times that of high-speed steel.

Excellent wear resistance: Service life 10-20 times that of traditional tool steel.

Good thermal stability: Maintains cutting performance at high temperatures of 600°C.

Diverse applications: From micron-sized PCB drill bits to giant mining rock drilling tools.

For super-hard tool distributors, Tungsten Carbide tools occupy about 60% of the metal cutting market. Particularly in the processing of automotive engine components, the use of PVD-coated Tungsten Carbide tools can improve production efficiency by 35% and reduce unit processing costs by 28%.

Medical companies have stringent requirements for the biocompatibility and machining precision of materials used in products such as bone drills and surgical instruments. Medical-grade Tungsten Carbide meets these demands through the following characteristics:

Ultra-fine grain structure: Average grain size of 0.5-0.8μm, ensuring sharp cutting edges.

Special surface treatment: Achieves mirror finish with a surface roughness of Ra 0.05μm.

Customized composition: Cobalt content of 6-10% balances strength and toughness.

For heat treatment companies, Tungsten Carbide molds perform exceptionally well in hot working environments. For example, in aluminum alloy die-casting production, nano-coated Tungsten Carbide molds can withstand:

Impact of 700°C molten aluminum.

2,000 thermal cycles per day.

Maintains dimensional stability within ±0.01mm.

The performance of Tungsten Carbide depends on three key factors: grain size, cobalt content, and coating technology. The following is a selection guide:

| Application | Grain Size | Cobalt % | Coating |

| Precision Cutting | 0.2–0.5 μm | 6–8% | TiAlN Nano |

| Heavy Interrupted Cuts | 0.8–1.2 μm | 10–12% | AlCrN Multilayer |

| Stamping Dies | 1.0–1.5 μm | 15–20% | Uncoated |

Optimization of cutting parameters: Increasing linear speed by 20% can extend tool life by 50%.

Edge treatment: A 25μm honed edge radius increases chipping resistance by 300%.

Storage conditions: Humidity should be controlled below 40% to prevent cobalt phase oxidation.

For super-hard tool distributors, the following value-added services are recommended:

Cutting Parameters: A 20% increase in cutting speed can extend tool life by 50%

Edge Preparation: A 25 μm hone radius improves chipping resistance by 300%

Storage: Maintain humidity below 40% to prevent cobalt oxidation

Build a machining database for grade recommendations

Offer tool reconditioning to extend lifespan by 30–50%

Provide cutting parameter training to enhance customer retention

From smartphone metal frame milling to wind turbine bearing machining, carbide remains the cornerstone of manufacturing. The global carbide market is projected to reach $27 billion by 2025, growing at 5.8% CAGR.

JoyJet – Your Carbide Solutions Expert:

Material R&D: Gradient-structure carbide for thermal shock resistance

Manufacturing: HIP (Hot Isostatic Pressing) technology eliminates internal defects

Support: Metallurgical analysis & failure diagnosis labs

Contact JoyJet’s technical team today for tailored carbide solutions!