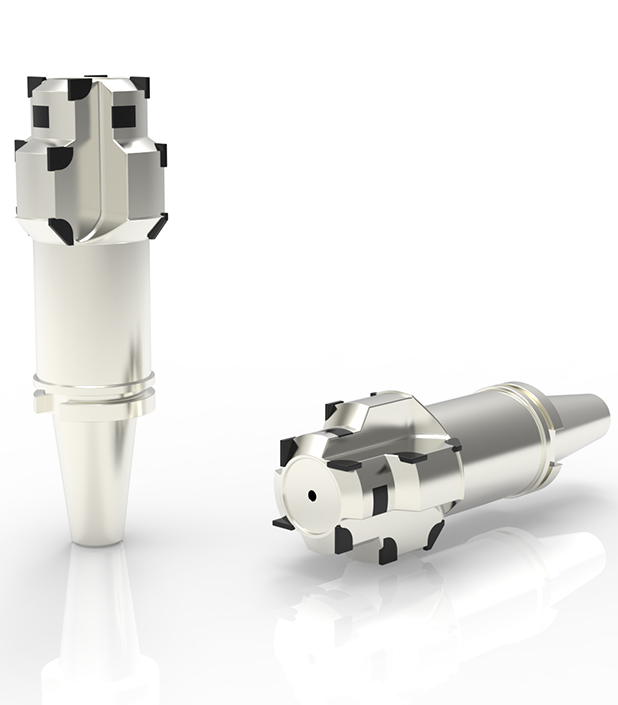

JoyJet PCD tools are ideal for machining non-ferrous metals and non-metallic materials. These PCD diamond tools offer exceptional wear resistance, with a tool life up to 50–100 times longer than that of carbide tools when processing aluminum alloys. PCD tools are also suitable for machining highly abrasive materials such as carbon fiber and high-silicon aluminum alloys. Additionally, our PCD tools are well-suited for precision electronic component manufacturing, capable of achieving a mirror-like surface finish with Ra ≤ 0.1 μm. Inquire now for diamond tools wholesale prices.

- Extreme hardness and wear resistance (HV8000–10000)

- Ultra-smooth cutting with low friction (Ra ≤ 0.1 μm)

- Superior heat and corrosion resistance

- Exceptional hardness up to HV8000–10000

- Precision ball nose for Ra ≤ 0.1μm finish

- Various specs and custom options available

- Ultra-hard diamond up to HV8000–10000

- Mirror edge finish to Ra ≤ 0.2μm

- 2/4/6-flute design for stable efficiency

- Ultra-hard diamond up to HV8000–10000

- Edge runout ≤ 0.005mm for stable cutting

- Custom geometries and specs available

- Ultra-hard diamond up to HV8000–10000

- Minimizes burrs and wall tearing for longer life

- High-rigidity carbide shank prevents breakage

As a diamond cutting tools manufacturer with over a decade of technical and manufacturing expertise, JoyJet provides PCD inserts (polycrystalline diamond tools) that are highly favored in the machining field for their outstanding performance.

Excellent wear resistance with long service life.

Our PCD tools can quickly dissipate heat, reduce heat accumulation in the cutting zone, and avoid thermal damage to workpieces and tools.

Small friction coefficient significantly reduces cutting force, reduces energy consumption, improves machining efficiency, and reduces tool wear.

Minimal thermal deformation ensures stable processing dimensions, especially suitable for precision machining with high accuracy requirements.

With comprehensive solutions including diamond tool sharpening service, we support customers in achieving sustainable and modern production goals.

Material Selection: Indentify the workpiece material you want to process.

Machining Process: Select the right type of Joyjet diamond tool (e.g., end mills, turning tools, drill bits) and specific tool geometry based on the required cutting operations.

Cutting Parameters: Consider the intended cut speed, feed rate, and cut depth to optimize the performance.

Tool Life: Opt for tools with longer lifetimes to minimize replacement frequency and enhance production efficiency.

Machining Precision: Select tools that meet the precision requirements of the machining task to ensure high quality results.