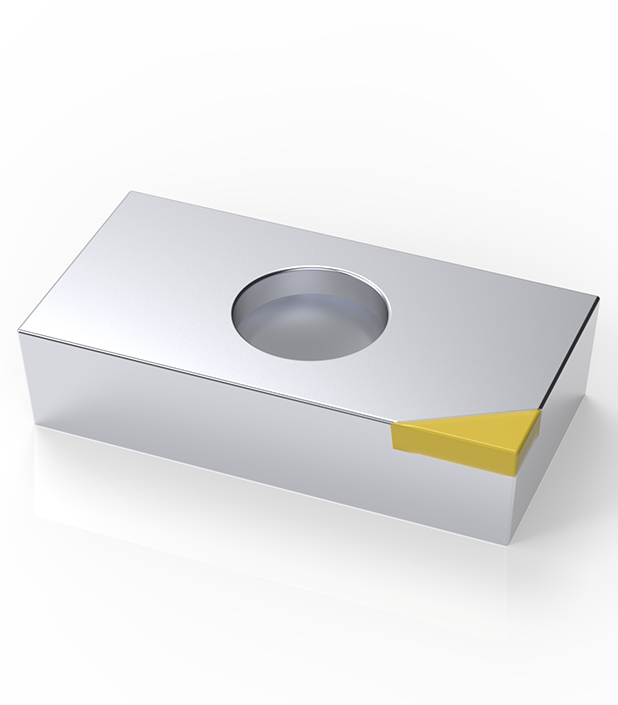

Replaceable cutting tool inserts help reduce production costs and give your tools a new lease of life. As one of the premium cutting inserts manufacturers in China, JoyJet offers a wide variety of indexable inserts, enabling us to provide the right diamond tools wholesale services for your specific application.

- Extreme hardness (≈8000 HV) with superior wear resistance

- Ideal for aluminum, copper, brass, and other non-ferrous metals

- Suitable for CFRP, fiberglass, graphite, and ceramics

- Hardness: 3000-5000 HV

- Heat Resistance: 1200°C+

- For hardened steel, cast iron, and alloys

- Extreme hardness (HV9000–10000) for ultra-precision cutting

- Excellent thermal resistance up to 1200°C

- Ideal for non-ferrous metals, composites, and high-temp alloys

- High hardness and wear resistance for high-speed cutting

- Excellent heat resistance up to 1200°C

- Ideal for machining cast iron, hardened steel, and alloys

- High precision with Ra ≤ 0.5 μm for superior finishes

- Excellent heat resistance (800–1000°C)

- High compressive strength for intermittent cutting