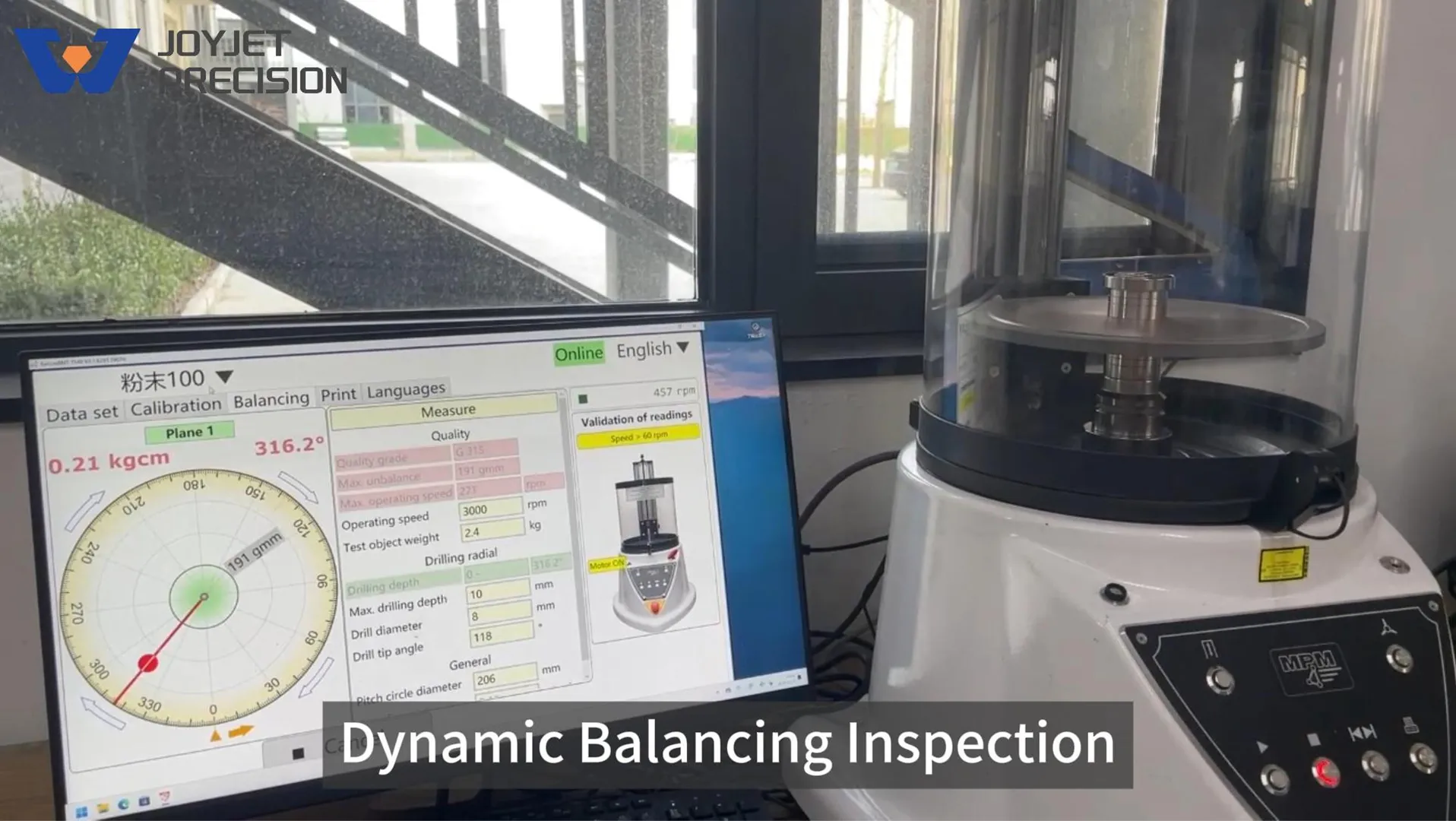

Grinding wheel dynamic balancing is performed to ensure the wheel remains stable during high-speed rotation, preventing vibration caused by imbalance and improving grinding accuracy and quality. The process is carried out using a dynamic balancing machine, which monitors vibration levels and guides the operator to add counterweights to correct imbalance. Proper balancing also extends the service life of the spindle and bearings while enhancing machining efficiency and final product quality.

Necessity of Dynamic Balancing

Improve machining accuracy: An unbalanced wheel produces vibration that affects grinding precision and surface finish.

Extend equipment life: Dynamic balancing reduces the load and impact on the spindle and bearings, prolonging their lifespan.

Ensure production safety: A severely unbalanced wheel rotating at high speed can pose significant safety risks.