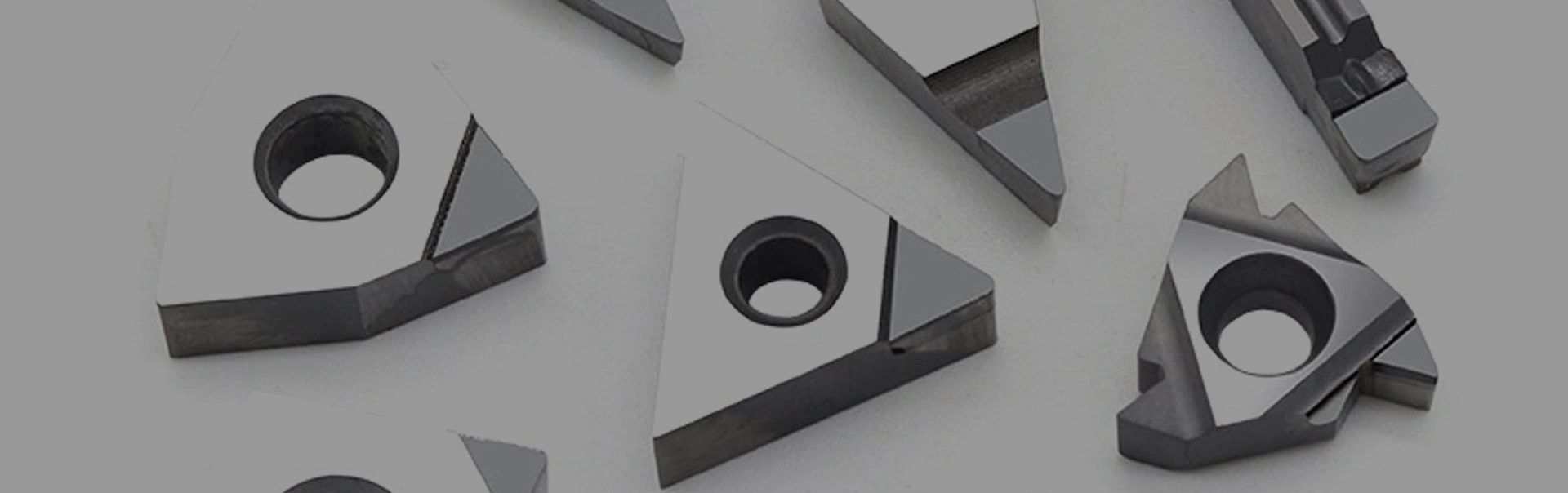

Diamond tools, utilizing diamond as the cutting component, are widely employed in high-precision and high-efficiency machining applications due to their exceptional hardness and wear resistance. Joyjet diamond tools and CNC cutting tools for sale are particularly well-suited for processing hard and brittle materials, such as cemented carbides, ceramics, glass, and semiconductor materials.

Shanks/blades are made of high-performance collective materials (carbide) to ensure collective buffer resistance during use.

Using high welding strength method—silver welding, laser welding, or vacuum welding—with inert gas protection. After welding, we use automatic grinding equipment to resharpen excess cutter head sections with an accuracy of ±0.01mm, ensuring the precision of tools like our MCD end mill.

Finally, the welding strength of the finished product and the precision of the tool are tested to ensure the quality and performance of products such as our PCD micro drill.

JOYJET's diamond tools factory in China produces more than 1000 kinds of superhard cutting tools, including standard series, customized solutions, special tools and other series of products, which comprehensively cover turning, milling, boring, drilling, reaming, honing and other finishing processes, and are widely used in the automotive industry, civil aviation, ultra-precision machining, general-purpose machinery, medical equipment and many other high-end precision manufacturing fields.