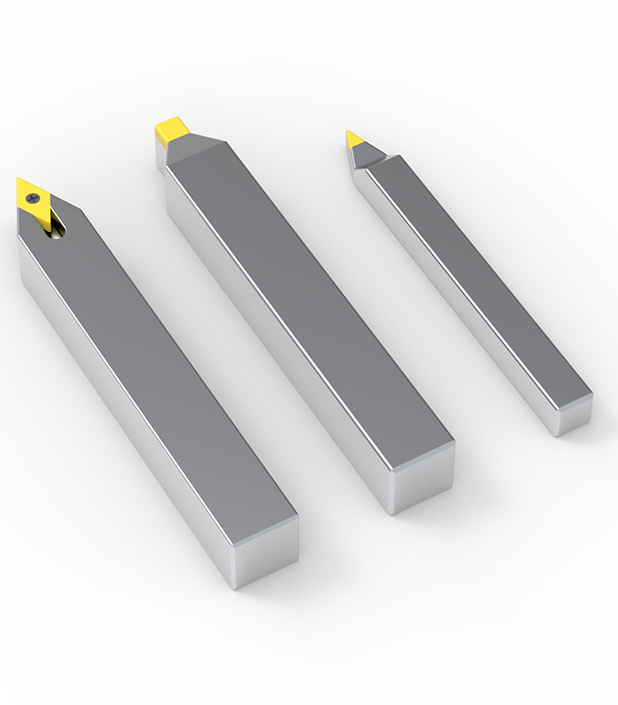

MCD tools, also known as monocrystalline diamond tools, are commonly used for ultra-precision machining of non-metallic materials such as sapphire, ceramics, silicon wafers, and tungsten carbide, as well as non-ferrous metals like aluminum and copper alloys. JOYJET's MCD tools deliver nanometer-level surface finishes. With a low coefficient of friction and minimal cutting resistance, our MCD tools are widely applied in high-end fields including ultra-precision machining, optical components, and electronic devices.

- Hardness: HV9000–10000

- Thermal Conductivity: 2000 W/m·K

- Workpiece roughness as low as Ra ≤ 0.01 μm

- Enables precise, burr-free cutting.

- Produces ultra-smooth surfaces.

- Ideal for aluminum, copper, and acrylic.

- Blunt Tip Design: High safety

- Quick recovery with virtually no scarring

- Compatible with HA, collagen, and PLLA fillers

- Diameter range: 0.1–3mm

- For metals and non-metals like Al, Cu, Ti, ceramics, PCB, graphite

- Used in precision molding, 3C, and aerospace fields

- Long tool life for high-precision machining

- Stable at 800–1000°C for dry cutting

- For HRC50+ steels, non-ferrous, and non-metal materials

JoyJet combines advanced manufacturing techniques with rigorous quality control to produce MCD tools that meet the demands of precision industries. Our tools are crafted using state-of-the-art machining and inspection equipment, ensuring consistent performance and reliability. As a manufacturer and user of our own tools, we understand real-world machining challenges and tailor our products to meet customer needs. Key benefits include:

Superior Precision: Monocrystalline diamond ensures exceptional hardness and wear resistance for precise machining.

Customized Solutions: Tailored tools based on customer specifications or technical drawings.

Extended Tool Life: Our professional diamond tool sharpening service helps maintain performance and durability, maximizing your investment.

High Satisfaction Rate: Trusted by industries worldwide for consistent quality and timely delivery.

For businesses looking for diamond tools wholesale, JoyJet offers reliable and high-quality solutions.